Unloading heavy equipment is a critical phase in any construction, industrial, or logistical operation. It requires precision, planning, and expertise to ensure the safety of personnel and the integrity of the machinery. However, this process is not without its challenges. From logistical hurdles to safety concerns, various factors can complicate the unloading of heavy equipment. In this comprehensive guide, we delve into the common challenges faced during heavy equipment unloading and explore effective strategies to overcome them.

Logistical Planning for Seamless Unloading

Understanding Site Constraints

When it comes to heavy equipment unloading, one of the foremost challenges is navigating the unique constraints of the site. Whether it’s limited space, uneven terrain, or accessibility issues, these factors can significantly impact the unloading process.

Strategies for Site Assessment

To tackle this challenge, conducting a thorough site assessment is paramount. This involves evaluating the terrain, identifying potential obstacles, and determining the best approach for equipment placement. By proactively addressing these challenges, teams can streamline the unloading process and minimize delays.

Coordination with Stakeholders

Effective communication and coordination with all stakeholders are essential for successful heavy equipment unloading. This includes collaborating with the equipment supplier, transport team, on-site personnel, and safety officers.

Establishing Clear Communication Channels

To overcome logistical hurdles, establish clear communication channels early in the planning stages. Regular meetings, progress updates, and contingency plans can ensure that everyone is on the same page and prepared to address any challenges that arise.

Ensuring Safety Protocols and Compliance

Rigorous Safety Training

Safety is paramount during heavy equipment unloading, given the potential risks involved. Adequate training for all personnel involved, including operators, riggers, and spotters, is crucial for accident prevention.

Implementing Safety Checklists

One effective strategy is the use of comprehensive safety checklists. These checklists should cover pre-unloading inspections, equipment setup procedures, and emergency protocols. Regular safety drills and refresher courses further reinforce these protocols.

Compliance with Regulations

Meeting regulatory requirements is another challenge in heavy equipment unloading. Regulations may vary based on location, equipment type, and industry standards.

Navigating Legal and Environmental Compliance

From obtaining permits to adhering to environmental regulations, navigating legal compliance can be complex. Engage with legal experts and environmental agencies to ensure full compliance and avoid costly delays or penalties.

Overcoming Equipment Size and Weight Challenges

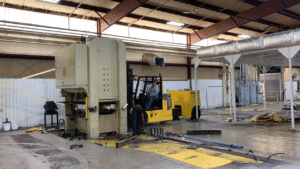

Handling Oversized Equipment

Unloading oversized equipment presents its own set of challenges, from maneuverability issues to weight distribution concerns.

Specialized Rigging Techniques

Specialized rigging techniques, such as using spreader bars or lifting beams, can help distribute weight evenly and minimize stress on the equipment and surrounding infrastructure.

Addressing Height Restrictions

For tall equipment, height restrictions pose a significant challenge during unloading. This is particularly true for indoor facilities or areas with overhead obstacles.

Implementing Height Clearance Strategies

To overcome this challenge, consider implementing height clearance strategies such as tilting trailers, adjusting lifting angles, or using low-profile trailers.

Efficient Equipment Setup and Assembly

Streamlining Assembly Processes

Once the equipment is unloaded, efficient setup and assembly are essential for project timelines and productivity.

Pre-Assembly Planning

Developing a detailed pre-assembly plan, including sequencing of components and tool requirements, can streamline the assembly process.

Utilizing Technology for Precision

Technological advancements, such as GPS-guided assembly or 3D modeling, offer precision and efficiency in equipment setup.

Benefits of Virtual Assembly Simulations

Virtual assembly simulations allow teams to identify potential issues beforehand, optimize assembly sequences, and reduce on-site assembly time.

Mitigating Weather and Environmental Factors

Adapting to Weather Conditions

Weather fluctuations, such as rain, snow, or extreme temperatures, can pose challenges during heavy equipment unloading.

Weather Monitoring and Contingency Plans

Regular weather monitoring and the development of contingency plans help mitigate risks associated with adverse weather conditions.

Environmental Impact Considerations

Unloading heavy equipment in environmentally sensitive areas requires careful planning to minimize ecological impact.

Implementing Eco-Friendly Practices

Utilize eco-friendly practices such as spill containment measures, dust suppression systems, and proper waste disposal to reduce environmental footprint.

In conclusion, heavy equipment unloading presents a range of challenges that require meticulous planning, coordination, and adherence to safety protocols. By understanding the logistical, safety, equipment-specific, setup, and environmental challenges, teams can develop effective strategies to overcome these obstacles. Through proactive measures, clear communication, and utilization of technology, the unloading process can be optimized for efficiency, safety, and successful project outcomes.