Crane operations are critical to construction, manufacturing, and logistics, requiring precision, expertise, and reliable equipment to ensure safety and efficiency. Rigging, an integral part of crane operations, plays a pivotal role in the secure lifting, moving, and placement of heavy loads. This article delves into the various aspects of rigging, its significance, best practices, and the role it plays in ensuring the success of crane operations.

Introduction to Rigging in Crane Operations

Rigging involves the use of specialized equipment to lift, secure, and maneuver heavy loads using cranes. It is the backbone of crane operations, ensuring that loads are safely attached and moved without damage to the load, the crane, or the surrounding environment. The complexity of rigging varies depending on the size, weight, and shape of the load, as well as the operational environment.

Proper rigging ensures:

- Stability and balance of the load during lifting.

- Prevention of accidents caused by equipment failure or improper techniques.

- Enhanced efficiency in material handling.

The importance of rigging cannot be overstated, as it ensures the safety of workers and the integrity of the operation.

Components and Types of Rigging Equipment

Rigging equipment encompasses a range of tools and devices, each designed for specific tasks and load capacities. The selection of appropriate rigging equipment is vital for the success of crane operations.

Slings

Slings are one of the most commonly used rigging components and come in various materials and configurations, including:

- Wire Rope Slings: Known for durability and strength, ideal for heavy loads.

- Synthetic Slings: Lightweight and flexible, suitable for delicate or irregularly shaped loads.

- Chain Slings: Durable and resistant to high temperatures, often used in harsh environments.

Shackles

Shackles are used to connect slings to loads or to other rigging components. They come in various types, such as anchor shackles and chain shackles, each suited for different lifting scenarios.

Hoists and Pulleys

These devices help in distributing load weight and provide mechanical advantage for lifting.

Spreader Bars and Lifting Beams

These are used to evenly distribute the weight of the load and prevent damage during lifting.

Hooks and Turnbuckles

Essential for securing and adjusting rigging configurations, these components add precision to lifting tasks.

Proper inspection and maintenance of rigging equipment are essential to ensure operational safety and longevity.

Safety and Risk Management in Rigging

Safety is paramount in rigging and crane operations. A single misstep can lead to catastrophic consequences, including property damage, injury, or loss of life. Risk management in rigging involves identifying potential hazards and implementing measures to mitigate them.

Common Risks in Rigging

- Overloading rigging equipment beyond its rated capacity.

- Incorrect rigging configurations leading to unstable loads.

- Wear and tear on rigging components causing failure.

Safety Guidelines

To ensure safe rigging practices:

- Conduct pre-operation inspections of all rigging equipment.

- Train personnel in rigging techniques and safety protocols.

- Use load charts and calculate load weight and center of gravity accurately.

- Adhere to regulatory standards such as OSHA and ASME guidelines.

Emergency Preparedness

Preparedness for emergencies, such as dropped loads or equipment failure, involves:

- Establishing clear communication protocols.

- Training workers in emergency response procedures.

- Having backup equipment and tools readily available.

Best Practices for Effective Rigging

To achieve optimal results in crane operations, adherence to best practices is crucial. These practices not only enhance safety but also improve operational efficiency.

Planning and Preparation

- Assess the load, environment, and equipment requirements before starting the operation.

- Develop a detailed lifting plan, considering factors such as wind conditions, ground stability, and load dimensions.

Proper Equipment Selection

- Choose rigging equipment suited to the load’s weight and characteristics.

- Ensure all equipment is inspected and certified for use.

Communication and Coordination

- Maintain clear communication between crane operators, riggers, and ground personnel.

- Use standardized hand signals or radios to convey instructions.

Load Stability and Balance

- Determine the load’s center of gravity and align it with the crane’s hook.

- Use spreader bars or lifting beams for long or irregularly shaped loads.

Regular Training

- Provide ongoing training to rigging personnel to keep them updated on the latest techniques and safety standards.

- Encourage a culture of safety and vigilance on-site.

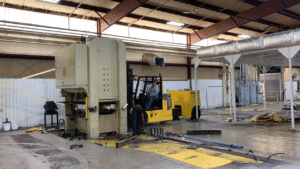

Alltracon: A Leader in Crane and Rigging Services

Alltracon is a trusted name in the field of crane and rigging operations, known for its commitment to safety, precision, and reliability. With years of experience and a team of skilled professionals, Alltracon provides comprehensive solutions for diverse lifting and rigging needs. Their state-of-the-art equipment and adherence to industry standards ensure the success of even the most complex projects. Whether it’s construction, manufacturing, or infrastructure development, Alltracon is dedicated to delivering excellence in every operation.

Conclusion

Rigging is an indispensable aspect of crane operations, ensuring that heavy loads are lifted and moved safely and efficiently. From selecting the right equipment to adhering to safety protocols, every step in the rigging process requires meticulous attention to detail. By following best practices and leveraging the expertise of service providers like Alltracon, industries can achieve unparalleled success in their crane operations while prioritizing safety and operational excellence.