Modern industry would look very different without cranes and rigging systems. They are the unsung heroes of progress—quietly enabling the growth of skylines, the movement of turbines, the relocation of factories, and the construction of vital infrastructure. Cranes and rigging are not just about lifting and lowering heavy loads; they are about precision, safety, and enabling industries to function efficiently at scale.

When we talk about heavy machinery or oversized loads, it is impossible to separate the conversation from cranes and rigging solutions. These systems bridge the gap between planning and execution, allowing projects that seem impossible on paper to become reality. Whether it is the relocation of an entire industrial plant, the installation of a wind turbine, or the unloading of massive aerospace components, cranes and rigging specialists make it happen.

In this article, we will explore how crane and rigging solutions support modern industries, examining their roles in construction, manufacturing, energy, aerospace, healthcare, and logistics. We will also consider how advancements in technology and best practices ensure safety, efficiency, and sustainability in operations that are often measured in millimeters, yet carry risks measured in millions of dollars.

The Foundation of Crane and Rigging in Industry

More Than Just Heavy Lifting

Cranes and rigging may appear, at first glance, to be about brute strength. However, what makes them indispensable is not just their ability to move thousands of pounds of equipment but to do so with incredible accuracy and foresight. A single miscalculation in a rigging plan can cause catastrophic equipment damage, financial loss, or even risk to human lives. This is why industries invest so heavily in skilled riggers, advanced crane systems, and careful planning.

The Human Expertise Behind the Machines

Every crane and rigging project involves people who understand load charts, center of gravity, rigging angles, and safety protocols. These professionals work like choreographers, coordinating between engineers, machine operators, and safety officers. The machines provide power, but the human expertise ensures that power is applied correctly. This collaboration of man and machine is what gives industries confidence to relocate delicate medical equipment, install massive generators, or erect 70-story skyscrapers.

Crane and Rigging in the Construction Industry

Building the Modern World

Construction is perhaps the most visible stage for cranes. Tower cranes rise above city skylines, mobile cranes navigate narrow streets, and rigging crews work quietly behind the scenes to place steel beams exactly where they are needed. Without cranes and rigging, modern architecture would be limited to a fraction of what is possible today.

In large infrastructure projects—bridges, dams, stadiums—the challenge is not just lifting, but lifting under constraints. A steel girder for a bridge may weigh several tons, but it must be lowered into place with pinpoint accuracy between support columns. Here, cranes become instruments of precision rather than raw force. Rigging crews calculate sling angles, spreader beam placement, and balance points to ensure every piece fits seamlessly.

Adapting to Urban Environments

Today’s construction industry increasingly deals with tight urban spaces. Cranes and rigging solutions make it possible to build upward instead of outward, maximizing limited land. By adapting mobile and crawler cranes with innovative rigging techniques, contractors can operate in spaces that once seemed too confined for heavy lifting.

Manufacturing and Industrial Relocation

Moving the Heart of a Factory

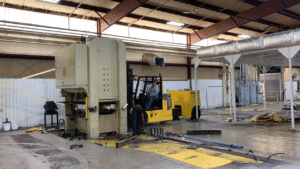

Inside manufacturing plants, cranes and rigging crews play a quieter but equally critical role. Machines like CNC mills, industrial presses, and robotic assembly lines are not simply unplugged and wheeled out like office furniture. Each piece of equipment is often bolted to foundations, calibrated to microscopic tolerances, and connected to complex utilities.

When companies relocate or upgrade their plants, crane and rigging solutions ensure that these machines are dismantled carefully, lifted without damage, and reinstalled with precision. A few degrees off in alignment can result in production errors, equipment wear, or costly downtime. The skill and technology applied here directly influence a factory’s profitability.

Enabling Growth Through Mobility

In today’s globalized economy, relocation is often part of growth. Companies move plants closer to raw materials, new markets, or tax-friendly zones. Without cranes and rigging, such moves would be financially unthinkable. These services transform relocation from a logistical nightmare into a manageable, phased project.

Energy Sector: Powering Progress

Traditional Energy

Power plants—whether coal, gas, hydro, or nuclear—rely on cranes and rigging for both construction and ongoing maintenance. Components such as turbines, boilers, and generators are massive and require not only lifting but strategic maneuvering within confined facilities. During scheduled shutdowns, rigging crews often work against the clock to remove, service, and reinstall components so that downtime is minimized.

Renewable Energy

As the world shifts toward renewables, cranes and rigging solutions have become even more crucial. The installation of wind turbines, for example, requires cranes that can lift nacelles weighing over 100 tons to heights exceeding 300 feet, often in remote or windy environments. Solar farms and hydro installations also depend on cranes for setting up large-scale infrastructure.

These projects demand not just lifting capacity but the ability to adapt to challenging terrains and weather conditions. Rigging crews in the energy sector combine technical expertise with problem-solving agility, ensuring that the shift toward sustainability remains on schedule.

Aerospace, Healthcare, and Specialized Sectors

Aerospace

Few industries demand more precision than aerospace. Loading and unloading aircraft parts, relocating test chambers, or installing satellites into testing rigs require cranes and rigging systems with absolute accuracy. Even a minor error in handling can cause millions of dollars in losses.

Specialized lifting frames, air-ride transport, and vibration-dampening rigging techniques are often used to protect delicate aerospace equipment. In this sector, cranes and rigging are not just support systems—they are part of the engineering process itself.

Healthcare and Laboratories

In hospitals and laboratories, cranes and rigging crews are tasked with relocating MRI machines, radiation therapy equipment, and other highly sensitive devices. These machines often weigh several tons but are also fragile. Rigging teams use specialized gear like air casters and gantry systems to move them without vibration or misalignment. The success of these moves directly impacts patient care and research capabilities.

Logistics and Ports

Global Trade in Motion

Ports are another arena where cranes dominate the landscape. Container cranes, gantry cranes, and mobile harbor cranes handle the loading and unloading of goods that fuel global commerce. Here, efficiency is measured in containers per hour, and downtime translates to global supply chain disruptions.

Rigging crews complement these operations when oversized cargo—such as heavy industrial components, mining equipment, or prefabricated modules—needs to be secured for shipping. The combination of cranes and rigging ensures that goods flow smoothly across oceans and borders.

Safety and Risk Management

The High Stakes of Heavy Lifting

The risks involved in crane and rigging work are immense. A dropped load can mean millions in damages and, worse, loss of life. Modern industries depend on strict adherence to safety standards and meticulous planning to mitigate these risks.

Rigging professionals spend as much time in planning rooms as they do on job sites. Load paths, structural tolerances, wind conditions, and emergency contingencies are carefully evaluated before a lift ever takes place. This emphasis on safety is not an afterthought—it is the very foundation of crane and rigging services.

The Role of Technology

Technology has transformed crane and rigging solutions. From computer-aided lift planning to real-time load monitoring, every stage is now supported by digital tools. Drones survey sites before lifts, 3D models simulate crane operations in confined spaces, and IoT sensors provide constant feedback during operations.

These advancements not only make operations safer but also improve efficiency, reducing downtime and lowering costs. For industries under pressure to deliver faster and cheaper, technology-enhanced crane and rigging solutions are a competitive advantage.

Sustainability and the Future of Crane and Rigging

As industries move toward greener practices, crane and rigging solutions are evolving as well. Electrically powered cranes, reusable rigging materials, and strategies to reduce fuel consumption are already becoming common. In the future, we may see cranes powered by renewable energy sources and AI-driven rigging plans that further reduce waste and risk.

Cranes and rigging will continue to play a central role in industrial transformation. As industries push toward automation, sustainability, and resilience, these solutions will adapt, making it possible to achieve goals that were once unimaginable.

About Alltracon – The Trusted Partner in Crane and Rigging

Among the many providers in this field, Alltracon has built a reputation as one of the most reliable and efficient service partners for crane and rigging projects. With decades of hands-on experience, a proven safety record, and advanced technology, Alltracon delivers end-to-end solutions that minimize downtime and maximize value. Whether relocating industrial plants, supporting construction projects, or managing sensitive equipment moves, Alltracon ensures every project is handled with precision, care, and efficiency.

Conclusion

Cranes and rigging may not always capture public attention, but they quietly support the backbone of modern industries. They make it possible to build higher, move smarter, and power the future. Their value goes far beyond heavy lifting—they provide the precision, safety, and adaptability that industries require to thrive in a world of increasing complexity.

From construction and manufacturing to energy, aerospace, healthcare, and logistics, crane and rigging solutions are inseparable from progress. As technology advances and industries evolve, their role will only grow stronger. Companies that understand and leverage these solutions gain not only operational efficiency but also the ability to turn ambitious visions into reality.