A Comprehensive Guide for Zero-Downtime Industrial Relocation

Moving large machinery is challenging under the best conditions. When that move must happen inside an active production environment, the complexity increases exponentially. Production lines must keep running, worker safety must be preserved, machinery accuracy cannot be compromised, and even a short unplanned shutdown can result in massive financial losses.

Manufacturers today face increasing pressure to modernize equipment, reconfigure layouts, expand capacity, or replace aging machinery—all while continuing daily operations. Whether it’s a CNC machine relocation, press movement, injection molding machine shift, or full line reconfiguration, executing such projects requires a carefully coordinated approach that balances operational continuity with precision engineering.

This guide explores every critical aspect of moving large machinery in active production environments, from planning and risk assessment to execution, compliance, and post-move optimization. It is designed to help facility managers, engineers, and operations leaders make informed decisions while avoiding costly disruptions.

Understanding Active Production Environments

An active production environment is any facility where manufacturing, assembly, or processing activities continue while machinery is being moved. Unlike full shutdown relocations, these environments demand that equipment moves occur alongside ongoing operations, often within tight time windows and restricted spaces.

In such settings, machinery relocation is not just a logistical task—it becomes a systems-level engineering challenge. Production schedules, employee movement, power systems, material flow, and safety protocols all intersect with the relocation process.

Even a minor oversight can ripple across the operation, causing bottlenecks, quality issues, or safety incidents. That’s why moving machinery in live facilities requires a far higher level of planning, coordination, and expertise than conventional equipment transport.

Why Moving Machinery During Production Is So Complex

The complexity arises from the need to protect three critical pillars simultaneously: people, productivity, and precision. Workers must remain safe, production output must remain stable, and the machinery must retain its alignment, calibration, and integrity.

Unlike empty facilities, active plants present constant motion—forklifts, operators, conveyors, and utilities are always in use. Machinery often needs to be disconnected and reconnected without disturbing nearby systems. Noise, vibration, and restricted access further complicate the process.

In addition, many industries operate under strict regulatory oversight. Food processing, pharmaceuticals, aerospace, and medical manufacturing environments impose additional cleanliness, validation, and documentation requirements during any equipment movement.

Strategic Planning: The Foundation of Success

Every successful machinery move in an active environment begins long before the first bolt is loosened. Strategic planning transforms a risky operation into a controlled, predictable process.

This phase focuses on understanding the machinery, the facility, and the production workflow. Engineers must evaluate load paths, floor capacity, overhead obstructions, power and data connections, and emergency access routes.

Key Planning Objectives

-

Maintain uninterrupted production wherever possible

-

Eliminate safety hazards for workers and contractors

-

Preserve machine accuracy and operational integrity

-

Minimize total relocation time

-

Ensure compliance with internal and external regulations

Planning also involves defining success metrics, such as maximum allowable downtime, acceptable vibration thresholds, and post-move performance benchmarks.

Risk Assessment and Hazard Mitigation

Risk assessment is especially critical in active environments. The presence of operating machinery, personnel, and materials increases the likelihood of incidents if hazards are not identified and mitigated early.

Risks may include load instability, collisions, electrical exposure, structural damage, or interference with adjacent equipment. Environmental risks such as dust, contamination, or temperature variation must also be considered.

Common Risk Categories in Active Production Moves

-

Personnel safety risks from moving loads

-

Equipment damage due to vibration or misalignment

-

Production disruption risks

-

Utility and power system interference

-

Structural and flooring stress risks

Each risk must be addressed with engineered controls, not assumptions. Temporary barriers, controlled movement zones, and real-time supervision are essential components of mitigation strategies.

Coordination with Production and Operations Teams

One of the most overlooked aspects of machinery relocation is internal coordination. Production supervisors, maintenance teams, safety officers, and line operators must all be aligned before execution begins.

Clear communication ensures that everyone understands when and where movement will occur, which areas are restricted, and what contingency plans are in place. Miscommunication can lead to unexpected equipment startup, blocked access routes, or unsafe interactions between workers and moving loads.

Successful projects treat machinery relocation as a shared operational event, not an isolated contractor task.

Scheduling Moves Around Live Production

Timing is everything when production continues. Machinery moves are often scheduled during off-peak hours, planned maintenance windows, shift changes, or partial line stoppages.

Rather than stopping an entire facility, many companies sequence moves in phases. This allows production to continue in unaffected areas while equipment is relocated in controlled zones.

Smart Scheduling Approaches

- Move equipment during low-output shifts

- Break large moves into smaller phases

- Coordinate with preventive maintenance cycles

These approaches reduce pressure on both operations and relocation crews while maintaining output targets.

Engineering Surveys and Machine Evaluation

Before any move, the machinery itself must be thoroughly evaluated. Weight distribution, center of gravity, anchoring points, and structural integrity all influence how the equipment can be safely lifted or rolled.

Older machines or custom-built equipment often lack clear documentation, making engineering surveys even more critical. Measurements must be verified, not assumed.

Engineers also assess how disassembly or partial dismantling may reduce movement risks. Removing auxiliary components can significantly improve safety and control during relocation.

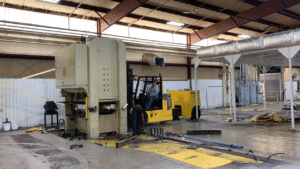

Specialized Equipment for Active Environment Moves

Standard forklifts or cranes are rarely sufficient for moving large machinery in tight, operational facilities. Specialized rigging and transport equipment allows precise, low-impact movement.

Air skates, hydraulic gantries, low-profile dollies, and synchronized lifting systems are commonly used to navigate confined spaces without disrupting nearby operations.

The selection of equipment depends on floor conditions, load weight, clearance limitations, and vibration sensitivity. Using the wrong tools can jeopardize both safety and production continuity.

Maintaining Safety in Live Facilities

Safety protocols must be stricter in active environments than in shutdown relocations. Workers unfamiliar with rigging operations may be present, and moving machinery introduces unfamiliar hazards into routine workflows.

Clear demarcation of work zones, visible signage, and active supervision are essential. Emergency procedures must be reviewed and rehearsed before work begins.

Personal protective equipment requirements may also change temporarily, depending on the nature of the move.

Utility Management and Isolation

Machinery relocation almost always involves interaction with utilities—electricity, compressed air, hydraulics, gas, water, or data systems. In active facilities, isolating these utilities must be done carefully to avoid affecting adjacent equipment.

Temporary rerouting, controlled shutdowns, and redundant systems are often used to maintain continuity. Utility reconnection after the move requires thorough testing before machinery is brought back online.

Improper handling of utilities is one of the leading causes of extended downtime during machinery moves.

Precision Alignment and Reinstallation

Once machinery reaches its new location, the work is far from over. Precision alignment is critical to ensure performance, product quality, and equipment longevity.

Even small deviations can lead to increased wear, vibration, or production defects. Laser alignment tools, leveling systems, and calibration instruments are commonly used during this stage.

Reinstallation also involves verifying anchors, torque specifications, and safety interlocks before commissioning begins.

Quality Control and Validation

In regulated industries, machinery relocation must be validated before full production resumes. This includes test runs, sample production, and quality inspections.

Validation ensures that the equipment performs exactly as it did—or better—before the move. Documentation is often required to satisfy internal audits or regulatory inspections.

Skipping or rushing this phase can result in quality issues that surface weeks or months later.

Managing Noise, Vibration, and Contamination

Active production environments are sensitive to disturbances. Excessive noise or vibration can affect nearby machinery, worker comfort, or product quality.

Special techniques such as vibration-dampening supports, controlled movement speeds, and environmental containment are used to minimize impact. In clean or controlled environments, additional measures may be needed to prevent contamination during equipment movement.

Contingency Planning for Unexpected Issues

Even with meticulous planning, unexpected challenges can arise. Floor conditions may differ from drawings, access routes may be obstructed, or weather may affect external stages of the move.

Contingency planning ensures that teams can respond quickly without improvising unsafe solutions. Backup equipment, alternative routes, and escalation protocols should be defined in advance.

Cost Considerations and ROI

While moving machinery during production may appear more expensive upfront, it often delivers a better return on investment than full shutdown relocations.

Avoided downtime, preserved customer commitments, and reduced restart issues frequently outweigh the additional planning and engineering costs. Decision-makers should evaluate total operational impact, not just contractor fees.

Industry-Specific Considerations

Different industries impose unique challenges during active machinery relocation. Food processing environments prioritize hygiene and contamination control, while aerospace facilities emphasize precision and documentation.

Understanding these nuances is critical to designing an approach that aligns with industry standards and operational priorities.

Why Experience Matters More Than Ever

Moving large machinery in active production environments is not a task for general movers. It requires deep experience in industrial rigging, operational coordination, and risk management.

The ability to anticipate problems, adapt to live conditions, and protect both people and productivity separates true specialists from standard contractors.

Why Alltracon Is the Right Partner for Active Production Moves

Alltracon specializes in moving large machinery within live, operating facilities, where safety, precision, and uptime are non-negotiable. Their team understands how to integrate machinery relocation into ongoing production without disrupting workflows or compromising equipment integrity. With advanced rigging systems, experienced engineers, and a proven planning methodology, Alltracon delivers controlled, efficient moves even in the most complex environments.

What Sets Alltracon Apart

-

Extensive experience in active production facilities

-

Advanced precision rigging and lifting technology

-

Detailed engineering and risk assessment process

-

Strong coordination with plant and safety teams

-

Proven track record across multiple industries

-

Focus on minimizing downtime and disruption

-

Commitment to safety and compliance at every stage

Final Thoughts

Moving large machinery in active production environments is one of the most demanding challenges in industrial operations. It requires far more than strength or equipment—it demands foresight, coordination, and precision engineering.

With the right planning, expertise, and execution partner, these complex moves can be completed safely, efficiently, and without sacrificing productivity. For organizations seeking to modernize, expand, or optimize their facilities while staying operational, mastering this process is not just an advantage—it’s a necessity.