Cranes are vital machines in the construction, engineering, and industrial sectors. They play a crucial role in lifting, moving, and transporting heavy materials and equipment on-site. Choosing the right crane for your project can significantly impact its success, both in terms of safety and efficiency. In this comprehensive guide, we will cover everything you need to know to select the right crane for your project, from understanding different types of cranes to considering factors like project scope, terrain, and load requirements.

Introduction

Choosing the right crane for your construction or industrial project is a critical decision that can influence the overall success, cost-efficiency, and safety of the project. Cranes come in a wide variety of shapes, sizes, and capabilities, each designed to serve different functions and work in specific environments. Understanding these differences is key to making an informed choice.

Whether you’re working on a high-rise building, a bridge, or a small commercial site, selecting the appropriate crane ensures that heavy materials are lifted safely and efficiently. This guide will walk you through all the essential factors to consider when making your decision.

Understanding the Different Types of Cranes

The first step in choosing the right crane is understanding the various types available. Different projects require different kinds of cranes, based on the environment, load capacity, and other factors. Let’s explore the most common types.

Mobile Cranes

Mobile cranes are versatile and widely used in construction because they can be easily transported to and from the job site. These cranes are mounted on a wheeled vehicle, making them ideal for short-term projects where the crane needs to move from place to place quickly.

Advantages:

- Flexibility to work in various locations.

- Fast setup time.

- Ideal for lifting and moving loads over short distances.

Common Uses:

- General construction projects.

- Maintenance tasks in industrial plants.

- Moving heavy materials across construction sites.

Tower Cranes

Tower cranes are typically used in the construction of tall buildings and skyscrapers. These cranes offer the highest lifting capacity and the ability to reach incredible heights. Tower cranes are fixed to the ground and have a long horizontal jib that allows them to lift heavy loads at great distances.

Advantages:

- Excellent for high-rise projects.

- Large load capacity.

- Capable of reaching extreme heights.

Common Uses:

- Skyscraper and high-rise construction.

- Large commercial building projects.

Crawler Cranes

Crawler cranes are mounted on a set of tracks (crawlers) rather than wheels. This design allows them to move on rough or uneven terrain, making them ideal for projects in challenging environments. They are often used in large-scale infrastructure projects, such as bridges and power plants.

Advantages:

- Suitable for rough terrain and unstable ground.

- No need for outriggers for stability.

- High lifting capacity.

Common Uses:

- Heavy-duty construction projects.

- Bridge and dam construction.

- Infrastructure development in challenging environments.

Rough Terrain Cranes

As the name suggests, rough terrain cranes are designed for job sites with uneven ground. These cranes are mounted on four large rubber tires and come equipped with outriggers for added stability. They’re perfect for projects in off-road areas or sites that are difficult to access with other types of cranes.

Advantages:

- Great for rough and uneven job sites.

- Compact design allows for easier transportation.

- Capable of handling heavy loads in difficult conditions.

Common Uses:

- Oil and gas field construction.

- Construction projects in remote or rugged areas.

- Infrastructure work in difficult terrains.

Overhead Cranes

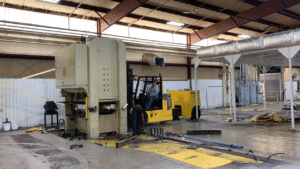

Overhead cranes (or bridge cranes) are most commonly used in industrial settings like factories, warehouses, and manufacturing plants. These cranes are installed above the ground and move along a track system, allowing them to transport heavy loads across large distances within a facility.

Advantages:

- Ideal for indoor environments.

- Efficient for repetitive lifting tasks.

- High load capacity.

Common Uses:

- Manufacturing and assembly line work.

- Warehousing and material handling.

- Shipbuilding and steel production.

Floating Cranes

Floating cranes are specialized cranes used for water-based projects. These cranes are mounted on barges and are often used in marine construction projects like building bridges, docks, or offshore structures.

Advantages:

- Perfect for water-based construction.

- Capable of handling large loads in marine environments.

Common Uses:

- Port construction and maintenance.

- Offshore drilling platforms.

- Marine salvage operations.

Factors to Consider When Choosing a Crane

Selecting the right crane involves more than just choosing the type. You must also consider specific factors related to the nature of your project, such as load requirements, terrain, and budget. Let’s explore the key considerations.

Project Scope

One of the first things to determine is the scope of your project. Is this a large-scale commercial project, or are you working on a smaller residential site? The size and complexity of your project will dictate the type of crane you need. Large projects might require tower cranes or crawler cranes, while smaller, short-term projects could be handled with mobile cranes.

Terrain and Job Site Conditions

The conditions of the job site are another crucial factor. If the site has uneven ground or is located in a remote area, you might need a rough terrain crane or crawler crane. On the other hand, for flat, urban environments, tower cranes or mobile cranes might be more suitable.

Load Capacity

Different cranes have varying load capacities, and exceeding these limits can lead to safety hazards. Ensure you know the maximum weight you need to lift and choose a crane that can handle that load safely. You should also account for the weight of any accessories, such as lifting slings or hooks.

Height and Reach Requirements

If you need to lift materials to significant heights, such as in high-rise construction, you’ll need a crane with a sufficient reach, like a tower crane. For projects with lower height requirements, a mobile or crawler crane might suffice. Consider both the vertical and horizontal reach capabilities.

Crane Mobility and Versatility

Consider whether you need a stationary crane or one that can move around the job site. Mobile cranes are ideal for projects that require frequent repositioning, while stationary cranes, like tower cranes, offer stability for long-term projects.

Budget Constraints

Crane rental or purchase costs can vary widely depending on the type and size of the crane. It’s essential to balance your project needs with your budget. Renting a crane might be a more cost-effective solution for short-term projects, while purchasing could make sense for long-term use.

Crane Rental vs. Purchase: Which is Better?

A common dilemma for project managers is whether to rent or purchase a crane. Both options have their pros and cons, and the right choice depends on your specific needs.

Renting a Crane

Renting a crane is often the more economical choice for short-term or one-time projects. It allows you to access the latest crane technology without the upfront costs of ownership. Additionally, crane rental companies typically handle maintenance, insurance, and transportation, reducing the overall hassle for the project manager.

Advantages of Renting:

- Lower upfront costs.

- Access to a wide range of crane models.

- Maintenance and repairs are handled by the rental company.

Disadvantages:

- Long-term rentals can become expensive.

- Limited control over the maintenance schedule.

Purchasing a Crane

Buying a crane makes sense for companies that regularly need crane services over an extended period. While the initial investment is substantial, ownership can save costs in the long run for companies that frequently use cranes.

Advantages of Purchasing:

- Long-term cost savings.

- Full control over the equipment.

- Can be an asset for your company.

Disadvantages:

- High upfront costs.

- Responsibility for maintenance, insurance, and storage.

Understanding Crane Load Charts and Weight Limits

Crane load charts are critical tools that outline the lifting capacities of a crane at various boom lengths and angles. Understanding how to read these charts is essential for safe crane operation and for ensuring that you select the right crane for your project.

Each crane has a maximum lifting capacity, which decreases as the boom extends or if the load is moved away from the crane’s centerline. Be sure to consider:

- Lift Radius: The distance from the crane’s center of rotation to the load.

- Boom Length: Longer booms reduce the crane’s lifting capacity.

- Load Weight: Always know the total weight of the materials being lifted.

Properly assessing the weight and reach requirements will help prevent accidents and ensure that the crane operates efficiently.

Crane Safety: Ensuring a Secure Work Environment

Safety should always be a top priority when working with cranes. Improper crane operation can lead to accidents, equipment damage, or even fatalities. To ensure safety, follow these best practices:

- Conduct Regular Inspections: Inspect cranes before use to ensure they are in good working condition.

- Provide Operator Training: Only certified and trained personnel should operate cranes.

- Use Proper Rigging: Ensure the load is properly secured and balanced.

- Monitor Weather Conditions: Wind, rain, and lightning can pose serious risks when operating cranes.

- Establish Clear Communication: Use hand signals or radios to maintain clear communication between crane operators and ground personnel.

Compliance with Regulations and Standards

Crane operation is heavily regulated to ensure the safety of workers and the public. In the U.S., cranes must comply with OSHA (Occupational Safety and Health Administration) regulations. These regulations cover everything from operator certification to equipment maintenance. Be sure to familiarize yourself with local and national crane safety standards to avoid penalties and ensure a safe working environment.

How to Find a Reliable Crane Rental Company

Choosing the right crane rental company is as important as choosing the crane itself. A reliable rental company will provide well-maintained equipment, qualified operators (if necessary), and excellent customer service. Consider these tips when selecting a crane rental provider:

- Check for Certifications and Accreditations: Ensure the company adheres to industry standards.

- Read Reviews and Testimonials: Look for feedback from previous clients to gauge the company’s reputation.

- Inspect Equipment: Ask to inspect the crane before rental to ensure it is in good working order.

- Inquire About Support Services: Does the company offer maintenance, repair, and operator services?

Conclusion

Choosing the right crane for your project is a critical decision that requires careful consideration of various factors such as project scope, terrain, load capacity, and budget. By understanding the different types of cranes available and evaluating your project’s specific needs, you can make an informed decision that ensures efficiency, safety, and success.

Whether you opt for a mobile crane, tower crane, or crawler crane, always prioritize safety, compliance with regulations, and working with a reliable crane provider. By following the guidelines in this ultimate guide, you can choose the perfect crane for your project and ensure that your lifting operations run smoothly and safely.

By considering these factors and understanding the options available, you’ll be well-equipped to choose the best crane for your next project.