In the world of manufacturing and industry, machinery installation is a critical step that bridges the gap between design and production. It’s the process through which the carefully crafted blueprints and plans become tangible, functional machines on the factory floor. This article delves into the machinery installation process, its key stages, challenges, and the crucial role played by trusted service providers like Alltracon.

Machinery installation is the cornerstone of industrial progress. Whether it’s setting up a new production line, upgrading existing equipment, or relocating machinery to a different facility, this process ensures that everything runs smoothly and efficiently. From the initial planning stages to the final calibration and testing, each step is integral to the success of the operation.

The Planning Phase

Blueprint Assessment

Before any actual machinery installation takes place, a thorough examination of the blueprints is conducted. This step helps identify potential challenges, such as spatial constraints, utility requirements, and safety considerations. It’s the blueprint assessment that lays the foundation for a well-executed installation.

Resource Allocation

Determining the necessary resources, including manpower, equipment, and materials, is essential. This phase also involves setting a timeline and budget, ensuring that the installation stays on track and within the allocated resources.

Safety Protocols

Safety is paramount in any machinery installation. Proper safety protocols are established, and workers are trained to follow them diligently throughout the process. This commitment to safety is where trusted service providers like Alltracon shine, as they prioritize safety at every step.

The Execution Phase

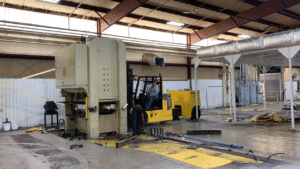

Equipment Delivery and Setup

Once the planning is complete, the actual installation begins. Equipment is delivered to the site, and the installation team sets up the machinery according to the specifications outlined in the blueprints. This phase requires precision and expertise to ensure that all components are in the right place. Custom fabrication may also be necessary to make the required modifications and deliver a smooth install. Make sure your millwright/ maintenance/ or rigging and installation company has certified welders on-staff, like Alltracon does, and can deliver on-the-spot same-day solutions.

Calibration and Testing

After the machinery is assembled, it undergoes a calibration and testing process. This step is crucial for guaranteeing that the machinery operates at peak efficiency, within tolerances, and meets your quality standards. Alltracon, delivers fine-tuning and adjustment/ commissioning/ millwright services, ensuring that every installation is meticulously tested for optimal performance.

Documentation and Compliance

Detailed documentation of the installation process is crucial for compliance and future maintenance. Alltracon’s commitment to quality extends to thorough record-keeping, photos, scope report, ensuring that clients have access to records for future reference.

Challenges in Machinery Installation

Precision and Alignment

Achieving precise alignment and calibration is one of the most challenging aspects of machinery installation. Even the slightest misalignment can lead to performance issues or safety concerns. Service providers like Alltracon are well-equipped to handle these challenges, thanks to their experienced technicians and state-of-the-art equipment.

Site-Specific Challenges

Each installation site comes with its unique challenges, such as limited space, access restrictions, or specific environmental conditions. Trusted providers like Alltracon have a proven track record of adapting to these challenges and finding innovative solutions.

Safety Compliance

Strict safety regulations are a constant concern in the industrial sector. Trusted providers like Alltracon prioritize safety compliance and invest in ongoing training for their teams to ensure that every installation meets or exceeds safety standards.

Conclusion

Machinery installation is the bridge that transforms plans and blueprints into operational reality. It’s a complex process that demands precision, expertise, and an unwavering commitment to safety and quality. Alltracon, as a trusted and leading provider of machinery installation services, has a track record of delivering excellence in every phase of the process. When it comes to turning your industrial dreams into reality, you can rely on Alltracon to get the job done right.