Manufacturing is the backbone of any industrialized economy, driving innovation, creating jobs, and delivering essential goods to the market. The modern manufacturing landscape is complex and dynamic, characterized by advanced technologies, stringent safety standards, and globalized supply chains. Within this intricate framework, full-service industrial contractors play a pivotal role, offering comprehensive solutions that enable manufacturers to focus on their core competencies. This article delves into the multifaceted contributions of full-service industrial contractors to modern manufacturing, highlighting their importance, services, and future trends.

Understanding Full-Service Industrial Contractors

Full-service industrial contractors provide a one-stop solution for a range of industrial needs, from construction and maintenance to equipment installation and facility upgrades. Unlike specialized contractors who focus on niche services, full-service providers offer end-to-end solutions, ensuring seamless project execution and coordination.

Key services offered by full-service industrial contractors include:

- Plant Construction and Expansion

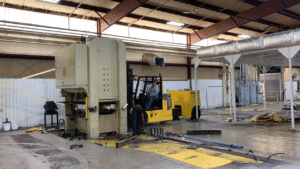

Full-service contractors manage every aspect of building or expanding manufacturing facilities, from design and engineering to construction and commissioning. Their holistic approach ensures that facilities are built to optimize workflow, comply with safety standards, and accommodate future scalability. - Equipment Installation and Integration

Manufacturing relies on complex machinery and equipment. Full-service contractors specialize in the installation, alignment, and calibration of industrial equipment, ensuring seamless integration into existing production lines. - Facility Maintenance and Repairs

To minimize downtime and extend the lifespan of equipment, full-service contractors provide regular maintenance, inspections, and repairs. Their proactive approach reduces unexpected breakdowns and enhances operational efficiency. - Energy Efficiency and Sustainability Projects

Modern manufacturers are under increasing pressure to reduce their environmental footprint. Full-service contractors design and implement energy-efficient systems, renewable energy installations, and sustainable facility upgrades. - Safety Compliance and Training

Adhering to regulatory requirements is critical in manufacturing. Full-service contractors ensure facilities meet OSHA and other industry standards while providing employee training to maintain a safe work environment.

The Role in Enhancing Efficiency

Efficiency is a cornerstone of manufacturing success. Full-service industrial contractors contribute significantly to streamlining operations in several ways:

- Seamless Project Management

By handling multiple aspects of a project, from design to execution, full-service contractors eliminate the need for coordinating multiple vendors. This reduces delays and miscommunication, leading to faster project completion. - Advanced Technology Integration

With expertise in the latest technologies, these contractors help manufacturers adopt automation, robotics, and smart systems. This not only boosts productivity but also reduces the margin for error. - Cost Optimization

A comprehensive service provider offers bundled solutions, which are often more cost-effective than hiring separate contractors for each task. Their expertise also ensures efficient resource utilization, further reducing costs.

Safety and Compliance

Manufacturing environments are inherently hazardous, with risks ranging from equipment malfunctions to chemical spills. Full-service industrial contractors prioritize safety in every project, ensuring compliance with all relevant standards. Their contributions include:

- Customized Safety Plans

Every manufacturing plant has unique risks. Full-service contractors develop tailored safety plans that address specific hazards while ensuring regulatory compliance. - Regular Audits and Inspections

Contractors conduct periodic safety audits and inspections to identify potential risks and rectify them before they escalate. - Emergency Preparedness

Contractors help manufacturers prepare for emergencies by installing safety equipment, conducting drills, and creating evacuation plans.

Supporting Sustainability Goals

Sustainability has become a key focus for modern manufacturers. Full-service industrial contractors help companies achieve their environmental goals by:

- Energy Audits

Identifying inefficiencies and recommending energy-saving solutions, such as LED lighting and energy-efficient HVAC systems. - Green Building Practices

Implementing eco-friendly materials and methods during construction or renovation projects. - Renewable Energy Integration

Installing solar panels, wind turbines, or other renewable energy sources to reduce dependency on fossil fuels. - Waste Management Systems

Designing systems for waste segregation, recycling, and safe disposal of hazardous materials.

Case Studies: Real-World Impact

- Automotive Manufacturing Facility Upgrade

A leading automotive manufacturer partnered with a full-service industrial contractor to upgrade its production line. The contractor managed equipment installation, facility expansion, and safety compliance, resulting in a 20% increase in output and a 15% reduction in operational costs. - Sustainable Packaging Plant Construction

A packaging company aimed to build an eco-friendly facility. The contractor implemented green building practices, renewable energy systems, and advanced automation, helping the company achieve LEED certification.

Challenges and Solutions

While full-service industrial contractors bring immense value, their work is not without challenges:

- Managing Complex Projects

Large-scale projects often involve multiple stakeholders and intricate logistics. Contractors mitigate these challenges with robust project management tools and communication strategies. - Keeping Up With Technological Advancements

Rapid technological evolution requires contractors to continuously upskill their workforce. Investing in training and partnerships with tech providers ensures they stay ahead. - Balancing Cost and Quality

Manufacturers often seek cost-effective solutions, but quality cannot be compromised. Contractors achieve this balance through efficient resource allocation and leveraging economies of scale.

Future Trends in Full-Service Industrial Contracting

The industrial contracting landscape is evolving in response to technological advancements and market demands. Key trends include:

- Increased Automation

Contractors are leveraging AI and IoT to enhance project planning, equipment installation, and facility monitoring. - Focus on Modular Construction

Prefabricated components and modular designs are becoming popular, reducing construction time and costs. - Sustainability as a Core Focus

Green practices will continue to dominate, with contractors integrating renewable energy and sustainable materials in their projects. - Enhanced Digital Tools

Software for project management, virtual simulations, and predictive maintenance is transforming how contractors plan and execute projects.

Alltracon: A Leader in Full-Service Industrial Contracting

Alltracon stands out as a trusted provider of full-service industrial contracting solutions. With expertise in construction, equipment installation, maintenance, and sustainability projects, Alltracon ensures seamless project execution, cost efficiency, and regulatory compliance. Partner with Alltracon to transform your manufacturing operations with innovative and reliable services.

Conclusion

Full-service industrial contractors are indispensable partners for modern manufacturers, providing the expertise, resources, and solutions needed to navigate the complexities of today’s industrial landscape. Their role in enhancing efficiency, ensuring safety, and supporting sustainability is critical to the growth and success of manufacturing businesses.